Tank terminals are vital hubs of the energy industry, handling large volumes of petroleum products daily. To maximize efficiency, these operations often utilize automated loading arms. These sophisticated systems offer a range of advantages that can substantially improve safety, accuracy, and overall effectiveness. Automated loading arms optimize the transfer process by precisely controlling the flow of materials, minimizing spills and ensuring accurate quantities. This not only reduces environmental impact but also minimizes operational costs.

- Additionally, automated loading arms boost worker safety by eliminating manual intervention in potentially hazardous conditions.

- By gathering real-time data on transfers, these systems can also generate data-driven recommendations for optimizing terminal performance.

Therefore,{integrating automated loading arms into tank terminal operations represents a strategic investment inimproved safety, increased efficiency, and sustainable practices.

Terminal Automation for Seamless Gantry Movement and Safety

Streamlining terminal operations through advanced automation technologies will become increasingly critical in the modern shipping landscape.

By integrating autonomous gantry systems, terminals can realize a substantially higher level of efficiency. These systems utilize cutting-edge technology to monitor the movement of goods with outstanding accuracy, minimizing the risk of incidents.

Furthermore, automated gantry systems improve overall safety by removing human operators from risky work environments. This also lowers the potential for harm but also streamlines workflow, increasing operational consistency.

Intelligent Gantry Automation: Precision Loading in Tank Terminals

In the dynamic realm of tank terminals, where efficiency and safety are paramount, intelligent gantry automation is revolutionizing loading operations. These cutting-edge systems leverage advanced sensors, robotics, and control software to achieve unparalleled precision and minimize human intervention. By seamlessly integrating with existing infrastructure, these automated gantries enhance operational productivity. They enable real-time monitoring of loading processes, ensuring strict adherence to safety protocols and regulatory compliance. With their ability to handle a wide range of tank sizes and product viscosities, these durable systems provide a comprehensive solution for optimizing loading operations in tank terminals.

Scada Integration for Enhanced Terminal Automation Control

In today's rapidly evolving industrial landscape, terminal automation is paramount for optimizing performance. Scada systems offer a powerful solution to streamline and enhance this process. By seamlessly integrating into existing terminal infrastructure, Scada provides real-time monitoring, control, and data visualization capabilities. This integration empowers operators to efficiently manage processes, leading to enhanced throughput, reduced downtime, and increased safety. The well-designed Scada system can optimize critical functions such as equipment monitoring, data acquisition, alarm handling, and reporting, consequently contributing to a more reliable and profitable terminal operation.

Automated Loading Arm Systems: Efficiency and Reliability in Bulk Liquid Handling

Automated loading arm systems revolutionize bulk liquid handling by providing a robust and efficient transfer process. These systems harness sophisticated technologies to effectively measure, deliver and monitor the flow of liquids between vessels and storage tanks. With computerized controls, loading arms reduce manual intervention, thereby increased productivity and reduced risk of human error. Furthermore, integrated safety features such as flow monitoring and emergency shutdown protocols ensure a safe and secure operating environment.

Real-Time Monitoring and Control: SCADA Applications in Tank Terminal Automation

Tank terminals rely heavily on efficient control systems to manage the complex processes involved in storing, transferring, and distributing various liquids. Implementing BATCH CONTROLLER SCADA (Supervisory Control and Data Acquisition) technology plays a crucial role in achieving this objective. By providing real-time visibility, SCADA systems enable operators to gain a comprehensive understanding of tank levels, flow rates, and other critical parameters. This awareness facilitates prompt decision-making in case of abnormalities.

Furthermore, SCADA systems facilitate remote control over various aspects of tank terminal operations. Operators can regulate equipment settings remotely to optimize efficiency. SCADA's robust data logging and reporting capabilities provide valuable analytics for performance monitoring, ensuring compliance with industry regulations and safety protocols. Through real-time monitoring and control, SCADA empowers tank terminals to enhance operational safety while minimizing risks associated with manual intervention.

Ariana Richards Then & Now!

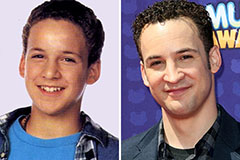

Ariana Richards Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Shane West Then & Now!

Shane West Then & Now! Tina Majorino Then & Now!

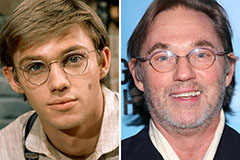

Tina Majorino Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!